Bypass Diodes Explained

You’ll notice we talk a lot about bypass diodes when explaining why our solar modules differ from traditional solar panels. Our modules are the only solar modules with bypass diodes on every cell. But what is a bypass diode, and why is having them on every cell such a big deal?

To understand why it’s beneficial to have bypass diodes on every cell, it will be helpful to learn about the technology we use, what makes up a cell, and how bypass diodes work.

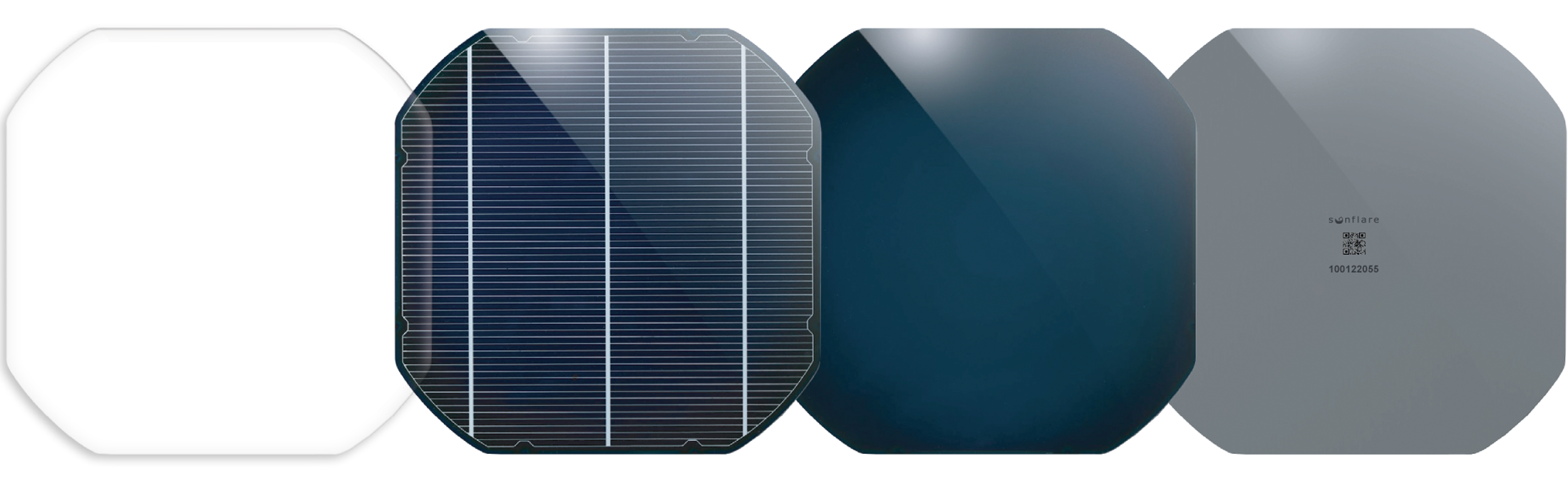

What Makes Up a Cell

Solar modules made with CIGS (Copper-Indium-Gallium-Selenide) technology are different than traditional glass (rigid) solar panels. To help understand how solar modules utilizing CIGS technology are different, it’s important to know what makes up a solar cell. We’ll get into more details on the technology part shortly.

Protective layer

The front sheet of the module is a well-tested 3M UBF 512 material. One of its primary purposes is to protect the module components from UV to prevent any damage it may cause. As long as the user does not remove the laminate, there will be no harm from UV.

Absorbant layer

The heart of every cell is the absorbing, or photovoltaic (PV) layer. This layer starts the process of creating power when the cells are exposed to sunlight. Electrons in the absorbing layer start warming up as the sun hits them and move around inside the cell until they get forced into the conductive layer.

Conductive layer

Once electrons are in the conductive layer, they soon hit a speed that forces them out of the cell through the conductive layer. Then the electrical current goes into your battery bank, creating an electrical load (power) for you to store.

Base layer

The base layer is like the skeleton for your solar modules. This layer holds everything together and determines how flexible the modules are. Array uses high-quality stainless steel for optimum strength and flexibility.

How Solar Modules Work

Simply, solar modules absorb power from the sun and then route that energy into your utility meter or a battery bank.

When sunlight comes in contact with the absorbent layer of your module, loose electrons (the negative charge of electricity) start warming up and moving around inside the cell. They become drawn to the conductive layer as they move around. The electrons soon hit a speed that forces them out of the cell as an electrical current and is fed into your utility meter to offset your electric bill or into a battery bank, creating an electrical load for you to store. The process repeats as long as the sun hits your solar panels. If you generate more electricity than you use and you are routing electricity into your utility meter, you may get credits on your bill from your local utility company, if applicable.

The longer sunlight is in contact with the module, the faster the electrons move around in each cell. The stronger the contact of the sun on your modules, the more energy they can generate.

What is CIGS Technology?

What exactly is CIGS (Copper-Indium-Gallium-Selenide) Technology, and why do we use it?

CIGS is an environmentally friendly, thin, versatile, flexible medium used as the semiconductor material for the absorbent layer of solar modules. The material allows modules to adapt to odd shapes and curved rooftops while maintaining efficient power output.

Each Array solar module cell starts with high-quality stainless steel and is layered with CIGS semiconductor materials. The result is a thin, lightweight, strong, and flexible solar panel. Traditional glass solar panels are thick, stiff, heavy, microcrack easily, and have limited installation options.

Solar modules constructed of CIGS thin-film materials are among the most advanced and efficient energy generation technologies available to the solar industry.

Better for the planet

Using CIGS technology reduces our carbon footprint on the planet. The manufacturing process does not rely on toxic chemicals like lead, cadmium, hydrofluoric acid, or hydrochloric acid. It requires less water, uses significantly less energy to manufacture than silicon panels, and Array recycles materials when spent.

More efficient in shade

Solar modules manufactured with CIGS technology are more light-sensitive, producing significantly more energy per year than traditional silicon panels. The increased efficiency is because they still generate energy in low-light situations, such as cloudy days, smokey conditions, or twilight hours. The increased sensitivity to light can significantly benefit those who live in areas with shorter days in the winters or an often cloudy environment such as the Pacific Northwest.

Withstands high impact

CIGS solar modules are precision-engineered to meet exact specifications, not only for outstanding performance and reliability but also for incredible strength. CIGS modules can withstand hailstorms, falling branches, and high winds.

Traditional rigid panels are made with glass, can easily be damaged with blunt force, and are susceptible to microcracking.

What is a Bypass Diode?

A diode is a device that allows an electrical current to flow in one direction (forward bias). A bypass diode allows alternate electrical current (reverse bias) when a cell on the solar module becomes shaded or blocked by debris.

Typical solar panels only have two bypass diodes, one every 18-24 cells. So if a cell on the panel is blocked, the bypass diode skips the entire string of cells. Sometimes a whole panel can be knocked out and not produce energy if two cells in different rows are shaded or blocked.

Array’s solar modules have bypass diodes on every cell. If a cell is shaded or blocked, the bypass diode will simply “skip” that specific cell, allowing the remaining cells to continue producing energy. This is achieved because bypass diodes are wired in parallel on each cell, providing a path for the current to continue through when a cell is blocked.

Why reverse bias is important

When bypass diodes are connected in reverse bias between solar cells, the electrical current continues to flow without stopping and has no blockage of output. The current is routed around the blocked or damaged cell and continues to route energy into your battery bank. The voltage output for the cell(s) blocked is subtracted from the solar panel's overall voltage output capability.

If solar cells have diodes that only allow forward bias, the current stops when the electrical current hits the blocked or damaged cell. The current stopping creates a “hot spot” in the cell and can cause permanent damage. You also will lose the voltage output for an entire row of cells and sometimes the whole panel, depending on which cell is blocked.

Efficient when shaded or blocked

Array modules are more efficient than traditional silicon panels in partial shade. All modules have bypass diodes for each cell. When a cell is shaded by trees, snow, other buildings, or debris, only that individual cell stops producing power.

Traditional solar panels have a bypass diode per string of cells. Therefore, that whole string will not produce power if just one cell is blocked. Since there are usually only three strings per panel, an entire panel can be knocked out if shaded across a single row.

Normal Load

Silicon Module

Array Module

Partial Shaded Cells

Silicon Module

Traditional solar panels only have one bypass diode per row, so if a cell on the panel is blocked, the bypass diode skips the entire string of cells. An entire panel can be knocked out and not produce energy if cells in different rows are shaded or blocked.

Array Module

Array’s solar modules have bypass diodes on every cell. If a cell is shaded or blocked, the bypass diode will simply “skip” that specific cell, allowing the remaining cells to continue producing energy.

Summary

Incorporating bypass diodes between every cell on a solar module drastically increases the productivity of the module. Your panels will generate more energy if a cell is blocked or damaged than a traditional panel with fewer bypass diodes, and your solar panels will last longer due to not having hot spots in shaded cells.

Partner individual bypass diodes with CIGS technology, and you have a literal powerhouse efficiently and sustainably generating energy for decades to come.